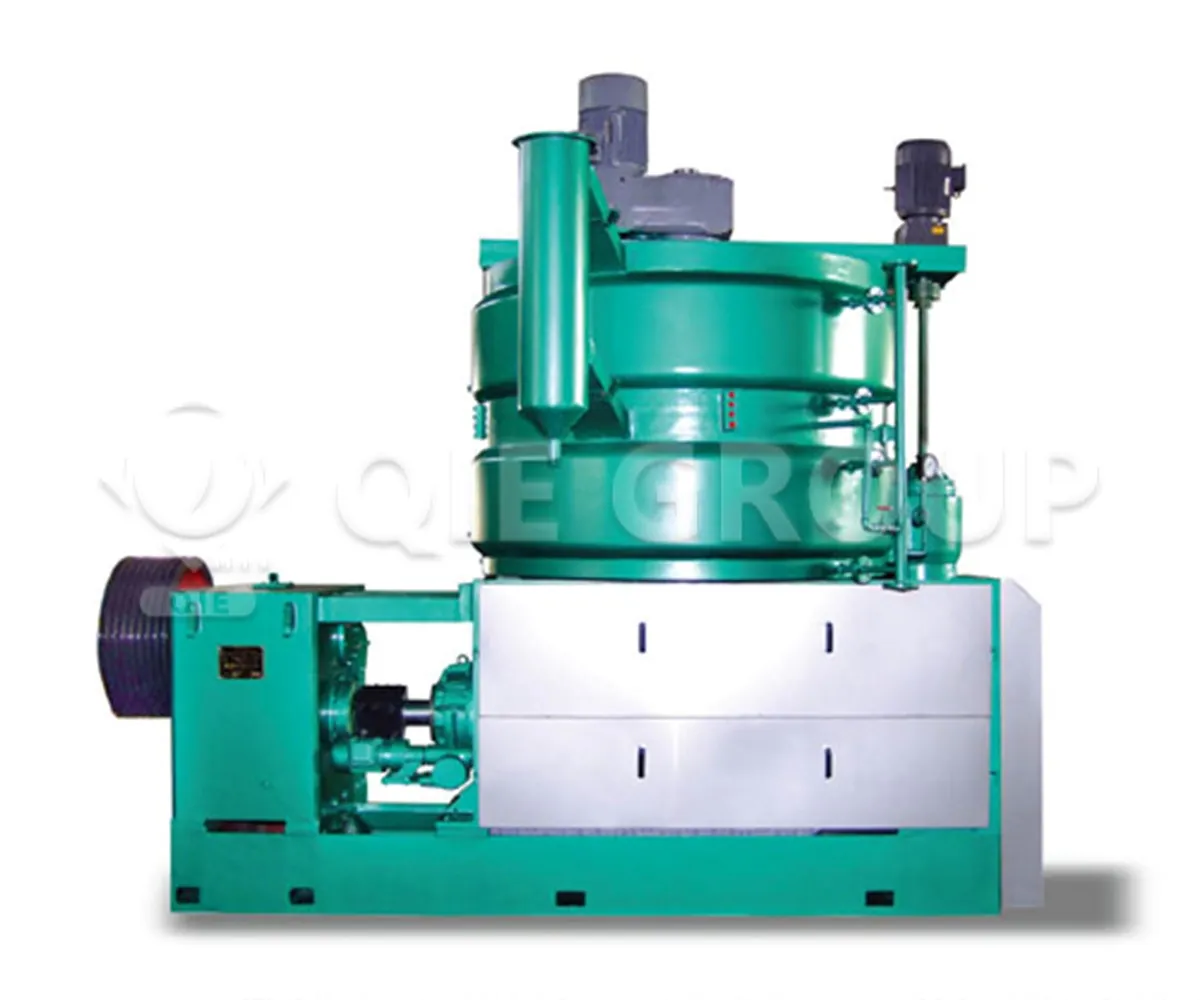

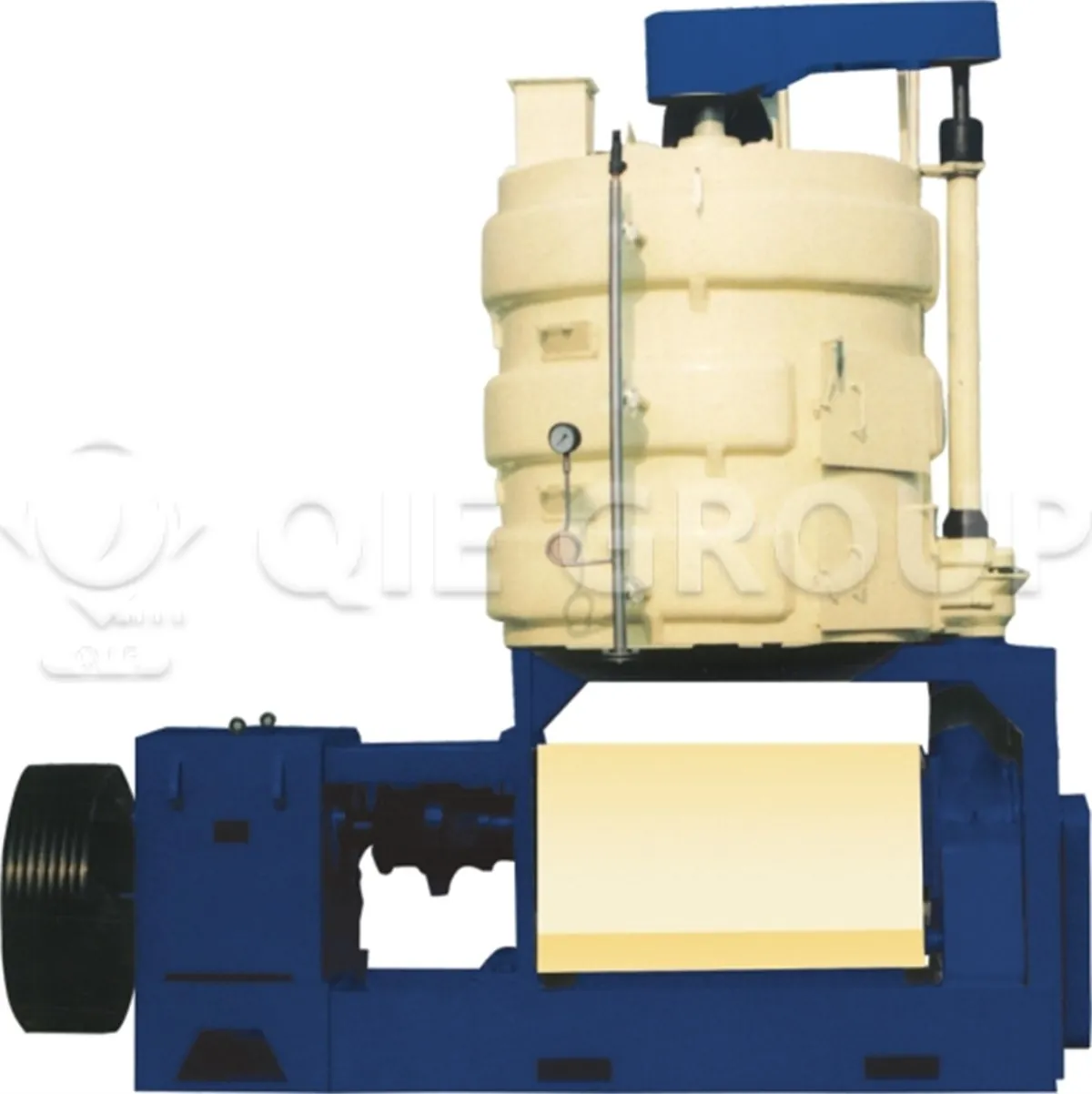

In the pressing process of peanuts and similar oilseeds with high oil content, traditional equipment often faces challenges such as insufficient oil yield, high energy consumption, and high residual oil content. QIE GROUP's screw oil press achieves the dual goals of energy saving and efficiency improvement by optimizing the screw blade structure, improving the sealing of the pressing chamber, and enhancing the efficiency of the power system.

Improve the shape of the spiral blades to increase pressing density and reduce oil loss.

Optimize the pressing chamber seal to ensure full compression of oilseeds.

Continuous production processes offer enhanced stability and significantly reduce energy consumption and maintenance costs.

Continuous operation not only increases production capacity but also improves process stability and energy efficiency, making it key to upgrading the pressing process in modern peanut oil plants. 🔗 Recommended Reading: ( Which company makes the best edible oil pressing equipment ?)

To help users understand the applicable scope of different equipment, we have compiled a comparison of the daily processing capacity, residual oil content of dry cake, and motor power of various models of screw oil presses:

| Equipment Model | Daily processing volume | Residual oil from dried biscuits | motor power |

|---|---|---|---|

| ZX200-3 | 7–10 TPD | 5–7% | 18.5kw |

| ZX28 | 40–60 TPD | 7–9% | 55 + 11 + 4kw |

| ZX32 | 90–100 TPD | 8–10% | 90 + 11 + 5.5kw |

| ZX320 | 100TPD | ≤8% | 110kW |

illustrate :

The residual oil rate of dried cake refers to the proportion of oil in the dried cake itself, while the residual oil rate is the unextracted portion of the total oil in the raw materials. Although they are of different magnitudes, the logic is the same.

Different models of equipment are suitable for different production capacity requirements, and the power and daily processing capacity are reasonably matched.

It can help companies select the appropriate equipment model based on their production capacity, efficiency and energy consumption requirements.

High-oil-content raw materials present three main challenges in traditional pressing equipment:

These factors have led to increased production costs, impacting the overall profitability of oil mills and making energy conservation and emission reduction an urgent need. 🔗 Recommended Reading: ( High Oil Yield Oil Pressing Machine Technical Solutions )

A medium-sized peanut oil processing plant in southern Vietnam processes about 25 tons of high-oil-content peanut raw materials every day. It used to use a traditional screw press with an oil yield of about 38% and a residual oil rate of 8.0%.

Implement optimization measures:

Adjusting the spiral blade design to increase pressing density

Improved pressing chamber sealing to reduce oil loss

Optimize the power system and screw speed to improve mechanical efficiency.

Precise control of extrusion pressure and feed rate to maintain continuous production.

Customer feedback: " After adopting our screw oil press, the oil yield increased by approximately 3.5% - 4 %, energy consumption decreased by approximately 20%, residual oil rate decreased by approximately 2.5%, the continuous production process improved overall production efficiency by approximately 15%, and maintenance costs also decreased significantly. "

The continuous operation process after adopting the QIE GROUP's screw oil press has achieved system optimization in raw material pretreatment, screw pressing, and residual oil recovery:

These innovations effectively solve traditional problems in the processing of "high oil content raw materials", achieving a win-win situation of energy saving, consumption reduction and high-quality output.

In terms of economic benefits, the energy-saving and consumption-reducing properties of our screw oil press directly lower production costs:

Overall costs reduced by approximately 12%-18%.

The equipment is highly versatile and suitable for oilseeds with high oil content, such as sesame and sunflower seeds.

Process improvements and routine maintenance can extend equipment lifespan and enhance operational stability.

Faced with the pressures of energy conservation, emission reduction, and market competition, peanut oil mills should prioritize upgrading their high-efficiency and energy-saving pressing equipment and mature technological processes.

Parameter optimization : Configure screw oil press parameters reasonably according to the characteristics of different raw materials.

Equipment maintenance : Strengthen daily maintenance to ensure long-term efficient operation.

Intelligent management : By combining data monitoring, automated production is achieved, continuously reducing energy consumption.

Continuous optimization : Focus on new technologies and process upgrades to improve oil yield and economic efficiency.