Have you ever encountered this situation: using the same raw materials, other companies produce more oil and the cake is more fragrant? It's not just good luck, but the equipment is really different.

With years of manufacturing experience in the oilseed industry, we've seen too many customers waste tens or even hundreds of thousands of yuan in profits because of a press that "looks similar." Don't underestimate those few hundred percent differences in oil residue—processing 10 tons of peanuts daily, reducing oil residue from 8% to 5% can earn you over 100,000 yuan more a year! This isn't an exaggeration; it's data from our real-world tests in Uganda, Nepal, India, and other places.

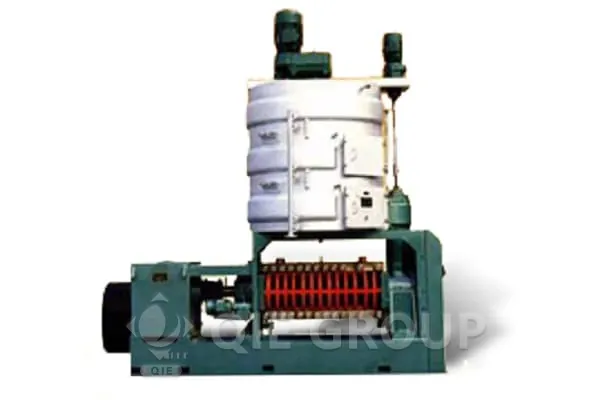

At QIE Group, we discuss the same question with our clients every day: how to maximize oil extraction efficiency while ensuring oil quality? Today, I'd like to share some firsthand experience and technical insights to help you maximize the value of every seed. [🔗: How to Choose Oil Pressing Equipment? 3 Key Points to Help You Select the Right Oil Press ]

Many old-fashioned screw presses focus only on pressure, neglecting the processing technology. They use crude temperature control and have a simplistic screw structure. The result? The oilseed cells aren't fully broken down, and the oil is locked inside the cake; or the temperature is too high, destroying the aroma and lowering the quality.

For example, when processing cottonseed, ordinary equipment typically leaves an oil residue of 7.5%, while our optimized variable-diameter screw and intelligent temperature control system can stably reduce the oil residue to below 4.8%. This isn't a theoretical value; it's a result of actual measurements from a renovation project we conducted for a large grain and oil mill in China.

A truly efficient oil press with a high oil yield doesn't rely on excessive pressure, but rather on the coordinated efforts of four dimensions:

Many people believe that higher temperatures result in faster oil extraction, but this is not the case. Different oilseeds respond completely differently to temperature and pressure. Our presses are equipped with multi-point temperature sensors and a pressure feedback system, which can automatically adjust the heating zone and compression ratio.

✅ High-oil sesame seeds are cold-pressed at low temperatures (60–80℃) to preserve their aroma and antioxidants;

✅ Soybeans are moderately heated to 100℃ to activate the fluidity of the oil and increase the oil yield by 3–5 percentage points.

This intelligent control, tailored to the specific materials, results in a more stable oil yield and purer oil quality.

The screw is the soul of the oil press. We use a variable diameter, variable pitch screw design, combined with multi-stage pressure rings, to achieve "progressive compression" of the material within the chamber.

Compared to traditional equidistant screws:

✅ Reduced slippage leads to increased shear force;

✅ The cell walls of oilseeds are broken more thoroughly.

High oil yield does not necessarily mean high energy consumption. Our equipment integrates a PLC intelligent control system, allowing operators to simply set the raw material type, and the machine will automatically select the optimal parameters.

✅ High-efficiency gearboxes and variable frequency motors reduce energy consumption by 20% compared to traditional equipment;

✅ Taking the ZX200A-3 automatic screw press as an example, the total power of the machine is only 18.5 kW, but it can achieve a stable oil yield of over 94%.

For oil refineries, equipment downtime means losses.

✅ The screw and pressing ring are made of high-strength alloy steel, with deep carburizing and special heat treatment, extending their service life by more than 3 times;

✅ Customer feedback indicates that after 6 months of continuous operation, only one routine lubrication is required, greatly reducing downtime costs.

| Technical Module | Advantages |

|---|---|

| Intelligent temperature control matching | Automatic blending of different oilseeds: cold-pressed sesame retains its aroma, while hot-pressed soybeans improve fluidity. |

| Optimize screw design | Variable pitch combined with progressive compression reduces slippage, increases shear force, and results in more thorough cell wall disruption. |

| Energy-saving and low-consumption operation | With PLC automatic control and a variable frequency motor, the total power consumption is only 18.5kW, saving 20% more electricity than the old model. |

| Durable and easy to maintain | High-strength alloy steel components with deep carburizing treatment extend service life by more than 3 times, requiring lubrication only once every six months. |

Case Study 1: Peanut and Sesame Crushing Project in Uganda

A Ugandan customer was experiencing an oil residue rate as high as 7.8% when using a traditional screw press. We replaced it with a ZY24 (202-3) screw oil press, equipped with an intelligent temperature control system. After starting production, the oil residue rate dropped to 4.6%. The customer excitedly said, "With the same raw materials, we produce nearly 2 tons more oil per month, and we recouped the equipment cost in just six months!"

Case 2: Nepalese Cold-Pressed Sesame Oil Workshop

Another client wanted to create a high-end cold-pressed sesame oil brand. We recommended the 6YY-230 hydraulic high-oil-yield oil press. The equipment occupies less than 10 square meters and can be operated by one person. Thanks to the low-temperature cold-pressing process, the oil has excellent purity and aroma, helping the client quickly enter the high-end market.

These are not accidental, but because we understand our customers' pain points: what they want is not just "usable", but "worth using".

We deeply understand that behind every piece of equipment lies the dream of a company. QIE Group is not only an equipment manufacturer, but also your technology partner.

1️⃣ 40+ years of industry experience, serving 130+ countries worldwide;

2️⃣ Independent R&D team continuously optimizes screw dynamics and material processes;

3️⃣ Full-process technical support, from factory layout and equipment selection to operation training;

4️⃣ A localized service network ensures timely response to installation, debugging, and after-sales issues.

We believe that behind every piece of equipment lies the dream of a family workshop or the hope for business transformation. Our mission is to help you achieve higher oil extraction efficiency and sustainable profits.

Q1: What raw materials are suitable for high-oil-yield oil presses?

A: This model can be widely used for various oil crops such as soybeans, peanuts, sesame, sunflower seeds, rapeseed, and cottonseed, and the spiral structure and temperature control system can be customized according to the characteristics of the raw materials.

Q2: How much can the oil yield of the equipment be increased compared to traditional presses?

A: Generally, the oil yield can be increased by 5-8%. For some raw materials (such as sesame and peanuts), the oil yield can be increased to more than 10% after proper pretreatment.

Q3: Is this oil press compatible with existing production lines?

A: Yes. QIE Group supports non-standard customization and intelligent upgrades, and can be seamlessly integrated with existing pretreatment, refining, and filling equipment.

Q4: Is machine maintenance complicated? Do operators need professional training?

A: Easy to maintain, the equipment is equipped with an intelligent monitoring and automatic alarm system; the user interface is user-friendly, and novices can get started after a short training period.

Q5: Can QIE Group provide a complete turnkey project for pressing and refining?

A: Of course. We can provide a one-stop turnkey solution from design, manufacturing, installation to commissioning, tailored to our clients' production needs.

"Choosing a good high-oil-yield press is like giving your factory a thinking brain."

If you are planning to build an edible oil processing plant or upgrade your edible oil production line, you might want to ask yourself first: Can this equipment help me maximize the value of every seed? Is it truly tailor-made for you, rather than a generic "standard configuration"?

We don't advertise; we only provide practical solutions. Whether you're a small, medium, or large oil refinery, QIE Group can help you find the most suitable machine.

Get free technical consultation and equipment quotation now