Soybeans are often classified as an “easy-to-process” oilseed. In engineering practice, however, this assumption is one of the most common causes of equipment selection errors. With an oil content typically ranging from 18% to 22%, soybean oil bodies are tightly embedded within a dense protein matrix, making oil release highly sensitive to pressure profile, temperature control, and mechanical shear.

In real-world projects, the core risk of soybean oil press selection is rarely insufficient nominal capacity. Instead, it lies in the hidden erosion of system efficiency and long-term operational stability: rising specific energy consumption, unstable residual oil levels, deteriorating meal quality, accelerated wear of key components, and increasing unplanned downtime. A single misjudgment at the selection stage can lock an entire plant into a cycle of low efficiency and high operating cost.

This article approaches soybean oil press selection from a full engineering perspective, moving systematically through raw material characteristics, process route selection, common engineering pitfalls, and rational decision logic, to support investors, plant managers, and technical teams in making sustainable, system-oriented decisions.

The physical and chemical properties of soybeans define the non-negotiable engineering limits of oil press applicability.

Soybeans have a moderate-to-low oil content, which inherently limits the economic effectiveness of pressing alone;

Oil bodies are encapsulated within a high-strength protein network, requiring progressive and controlled structural disruption rather than instantaneous high-impact force.

Across multiple soybean pre-pressing projects, it has been consistently observed that increasing pressing intensity beyond a certain threshold does not proportionally increase oil recovery. Instead, it often results in cake collapse and restricted oil drainage paths.

Soybean protein content is typically around 40%;

During pressing, this high protein fraction tends to form a dense and resilient cake structure, impeding continuous oil flow;

Improper compression modes can shear the cake into excessive fines, directly impairing downstream extraction permeability and filtration performance.

From an engineering standpoint, cake structural integrity is often more critical than peak pressure values in determining effective soybean oil recovery.

Soybean proteins are highly sensitive to heat, particularly in the presence of moisture;

Excessive thermal exposure can cause irreversible protein denaturation, significantly reducing soybean meal feed value;

Soybeans exhibit low tolerance to high shear and aggressive mechanical stress, which can lead to: severe cake pulverization; elevated impurities in crude oil (phospholipids, fines); accelerated wear of pressing components.

Engineering conclusion: For soybeans, controlled, gradual pressure application is systematically superior to high-shear, high-impact processing strategies.

Oil press selection must be evaluated within the context of the overall process route it serves.

Applicable only when:

Processing capacity is very small;

Production targets niche or specialty markets (e.g., artisanal or organic oils);

Economic value of soybean meal is not a primary concern.

Engineering reality:

Residual oil content after full pressing is difficult to reduce economically below 5%;

Attempts to force lower residual oil levels through higher pressure and temperature significantly degrade meal quality;

Overall oil loss and energy consumption remain high.

In large-scale commercial operations, full pressing is not a simplified solution—it is often a cost-intensive compromise.

For medium- and large-scale soybean plants, this route is both the mainstream and the inevitable choice.

The engineering objective of pre-pressing is not maximum oil removal, but rather to:

Form a porous, mechanically stable press cake;

Stabilize residual oil content within the 12%–18% range;

Create optimal mass-transfer conditions for downstream solvent extraction.

In multiple soybean projects exceeding 300 TPD, experience shows that aggressively targeting residual oil levels below 12% often reduces extraction efficiency, increases solvent losses, and raises total system energy consumption—ultimately lowering overall plant profitability.

Standalone presses offer flexibility and lower initial investment, but suffer from low efficiency, high labor dependency, and poor consistency in continuous large-scale operation.

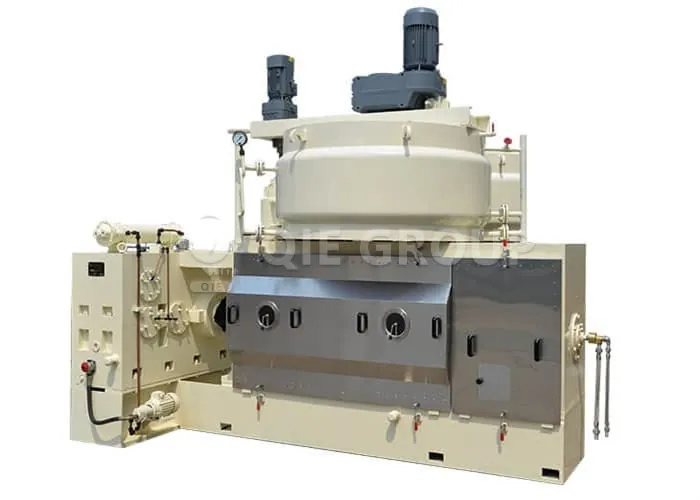

Continuous production lines, integrating cleaning, cracking, conditioning, flaking, cooking, continuous screw pressing, and cake handling, provide superior stability, automation, and energy optimization.

Practical engineering threshold:

💡 Once daily capacity exceeds 100 TPD, or when long-term economic performance is prioritized, pre-pressing combined with extraction becomes a prerequisite rather than an option.

Selecting equipment based solely on nominal throughput while ignoring compatibility with soybean material behavior.

Consequences:

Forced operation at excessive speed or pressure;

Severe cake pulverization and unstable residual oil content;

Escalating energy consumption and accelerated wear of critical components.

Treating the oil press as an independent machine rather than a system component.

Consequences:

Press cake structure mismatched with extractor design, increasing solvent consumption;

Crude oil impurity levels exceeding refining design limits, raising refining losses and instability;

Overall plant efficiency constrained by a single mismatched unit.

Failing to account for seasonal and regional variations in soybean moisture, variety, and protein rigidity.

In practice, soybeans from different origins exhibit markedly different structural and hydration behaviors. When press equipment operates within a narrow process window, frequent adjustments—or even stoppages—become inevitable.

💡 This is not an operational issue. It is a system design error made at the selection stage.

Engineering evaluation should prioritize:

Effective daily throughput under ≥22 hours/day continuous operation;

Compatibility with upstream preparation and downstream extraction capacities;

A 10%–15% design buffer to ensure long-term stability.

A pre-press residual oil range of 12%–18% represents the optimal balance between pressing effort and extraction efficiency;

Pushing below this range typically amplifies fines generation, energy demand, and mechanical wear, eroding system-level benefits.

Key evaluation criteria include:

Specific energy consumption per ton of soybeans;

Service life of core components (screws, cage bars);

Frequency of parameter adjustments;

Tolerance to raw material variability.

Core insight: A soybean oil press is not merely an efficiency tool—it is a stability anchor within the entire process system.

Q1: Can soybeans be processed economically using pressing only?

A: Not at industrial scale. Pre-pressing combined with solvent extraction is the established economic route.

Q2: Is lower residual oil after pre-pressing always better?

A: No. Excessively low residual oil typically reduces overall system profitability.

Q3: Do different soybean origins require different presses?

A: Not necessarily different presses, but sufficient process adaptability is essential.

Selecting a soybean oil press is not a matter of comparing equipment specifications. It is a strategic decision concerning process route alignment, system integration, and long-term operational objectives.

When project goals emphasize:

Stable oil and meal quality;

Controlled energy and maintenance costs;

Flexibility toward future capacity expansion and raw material variability;

Fragmented equipment procurement is rarely sufficient.

QIE Group has extensive global project experience in soybean oil extraction processes. If you are looking to build an efficient, stable, and economical soybean oil processing plant, or would like to learn more about our system-level engineering solutions, please contact our technical team. We will provide comprehensive support throughout the entire process, from process design and core equipment integration to automation control and installation and commissioning, helping you maximize your return on investment.