In the modern edible oil processing industry, low-temperature pressing technology is gradually becoming a new development direction. Compared with traditional high-temperature oil pressing methods, low-temperature pressing not only improves oil quality, but also effectively preserves the activity of protein in the meal, increasing the utilization value of the meal and helping oil mills achieve higher economic value.

Low-temperature pressing utilizes mechanical pressing at lower material temperatures, avoiding nutrient loss and oil oxidation caused by high temperatures. For manufacturers pursuing high-end, healthy edible oils, this process significantly enhances product competitiveness. Furthermore, the high protein retention rate in the meal allows for widespread use in feed or food processing, achieving dual benefits of both oil and meal.

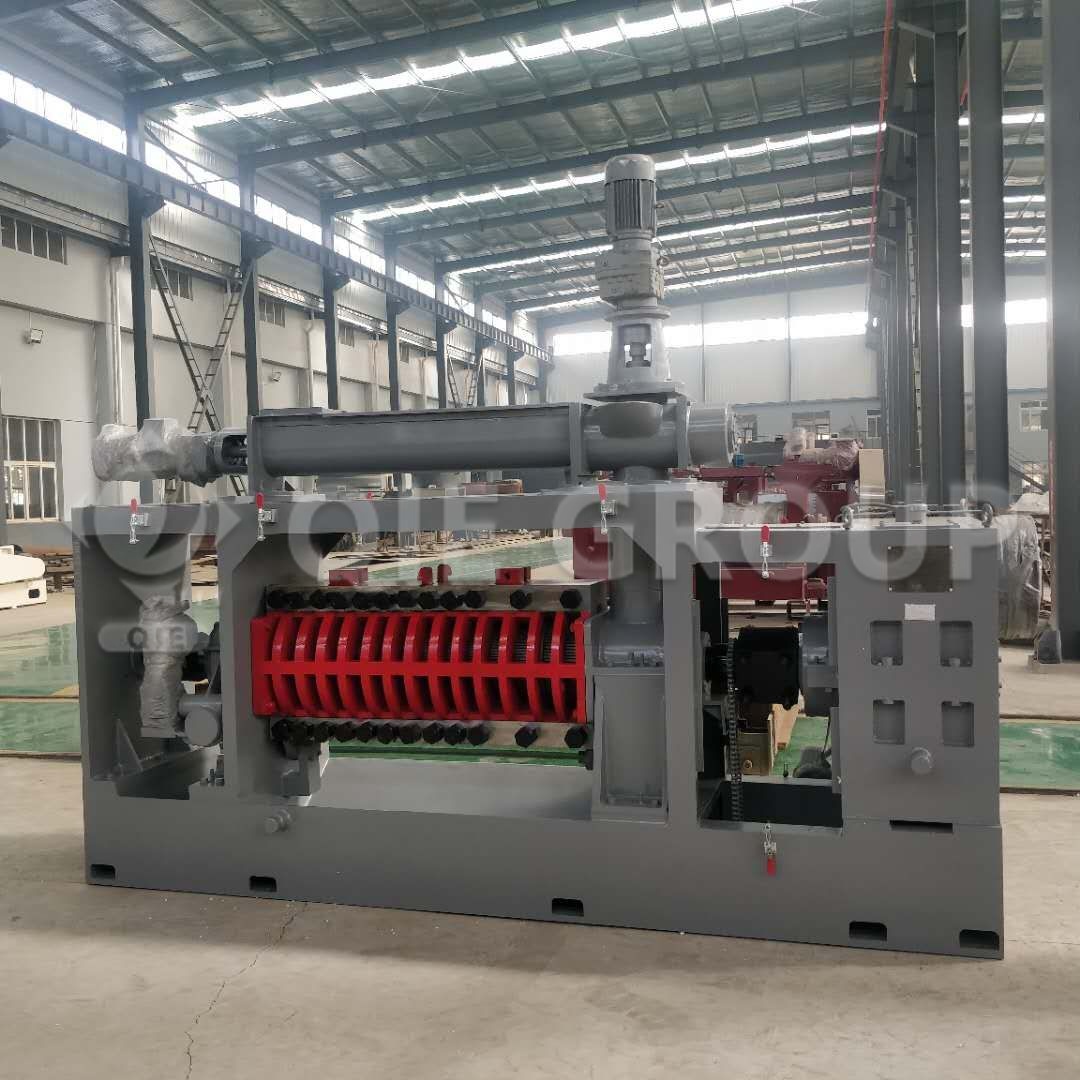

Our twin-screw oil presses utilize twin-screw extrusion technology, ensuring more even pressure distribution within the press chamber, resulting in a more complete compression, effectively increasing oil yield and reducing residual oil. Compared to traditional single-screw oil presses, the twin-screw structure adapts to the characteristics of different oils, ensuring a more stable pressing process and more thorough oil extraction. Furthermore, the efficient self-cleaning between the screws reduces clogging and wear, extending equipment life.

The key to low-temperature pressing lies in controlling the pressing temperature. Our twin-screw oil presses are equipped with an intelligent temperature control system that precisely controls the temperature during the pressing process (automatically adjusting according to the specific raw material). This effectively prevents high temperatures from damaging the protein structure, significantly reduces the rate of denaturation, and improves the nutritional and economic value of the meal. Furthermore, the low temperature environment better preserves the natural flavors in the oil. For example, the volatile aromatic components in peanut oil are retained at a rate of over 90%, significantly improving the sensory quality of the finished oil.

📢 Want to improve the oil production rate of your oil refinery? Contact QIE Group now

If you're looking for efficient, stable, and low-cost oil processing equipment, or want to increase your oil yield through equipment upgrades, we have professional solutions for you!