Flaxseed oil, rich in alpha-linolenic acid, vitamin E, and natural antioxidants, With the growing demand for healthy and nutritious edible oils, cold pressing technology has become the preferred choice for the high-end market.

Flaxseed cold pressing applies mechanical pressure at low temperatures, strictly controlled below 60℃, to avoid destroying heat-sensitive nutrients.

Seed Cleaning & Pre-treatment: Removal of stones, dust, and impurities to ensure raw material purity.

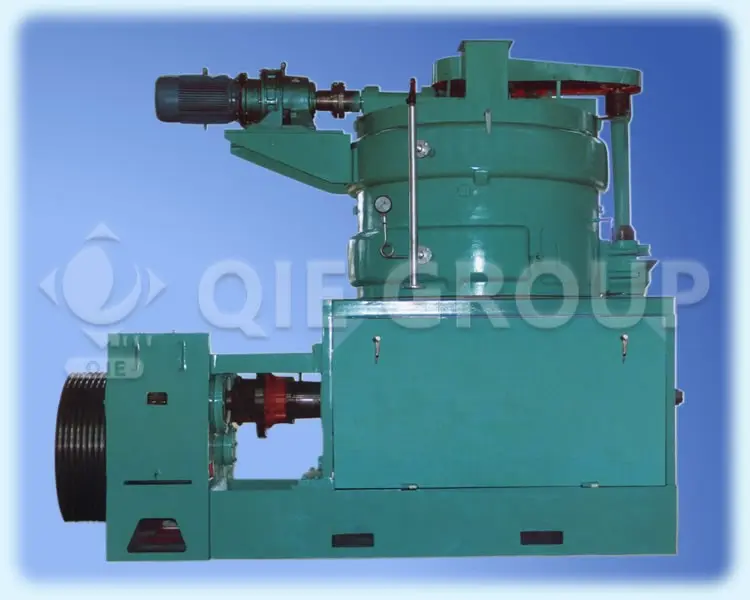

Low-Temperature Pressing: The spiral cold press slowly increases pressure to extract oil without adding any chemical solvents.

Fine Filtration: Cold filtration removes phospholipids and residues, producing edible-grade crude oil directly.

Compared with hot pressing: Cold pressing retains the maximum nutritional value, though the oil yield is generally 10–15% lower than hot pressing.

Model | Capacity | Motor power | Dry cake residual oil | Dimension (L*W*H; mm) | Weight(kg) |

LYZX28 | 40-60T/D | 45+11KW | 15-19% | 3783×3038×3050 | 9600 |

Low pressing temperature, minimizing protein denaturation in the oil cake;

Well-designed structure, easy operation and maintenance, durable performance;

Equipped with built-in temperature and moisture control devices;

Capable of fully automatic and continuous operation.

Configurable compact cold press units with daily capacity ranging from 1–10 tons;

Flexible integration of cleaning, pressing, and filtration modules; space-saving and cost-effective, ideal for start-ups and specialty health oil projects.

Customized complete lines combining pre-treatment + cold pressing + refining (daily capacity 10–500 tons);

Optional refining modules to produce Grade 1 premium edible flaxseed oil.

Natural cold-pressed oil label: solvent-free, non-GMO, rich in omega-3;

Perfect for premium health products, baby nutrition oils, and dietary supplements.

40 years of oil machinery experience with patented cold pressing technology (Patent No. ZL2023XXXXXX).

On-site engineering support, customized process design, plant layout, installation, and operator training.

Exported to 130+ countries; a 300TPD flaxseed oil project in Kazakhstan achieved industry-leading oil yield.

👉 Choosing QIE means more than choosing equipment – it means choosing long-term profitability and guaranteed oil quality.

Looking to set up a flaxseed oil production line?Contact QIE Group today to get a tailor-made solution and investment quotation, and enter the growing high-end healthy oil market with confidence.