Ethiopia, located in the Horn of Africa, is quietly emerging as a major player in the global sesame industry. As one of Africa's largest sesame producers, Ethiopia generates over 400,000 tons of sesame annually, with more than 70% exported to high-end markets such as China, Japan, Israel, and the Middle East. However, for a long time, most of this sesame has been exported as primary raw materials, with a low rate of deep processing and insufficient added value.

As global consumer demand for healthy, natural, cold-pressed sesame oil continues to grow, Ethiopian investors are beginning to focus on the deep processing of sesame oil, driving local agriculture up the value chain. High-quality cold-pressed sesame oil not only retains the natural flavor and rich nutrients of sesame, but also has become a new favorite in the international market due to its absence of chemical residues.

Cold pressing, due to its low-temperature pressing characteristics that preserve natural flavor and nutrients, is becoming the mainstream choice in the high-end sesame oil market. However, cold pressing places higher demands on equipment precision, material durability, and process control.

1️⃣ Improper temperature control will significantly reduce the oil yield;

2️⃣ Insufficient pretreatment can easily lead to an increase in residual oil content in the oilseed cake;

3️⃣ Low level of automation and high labor costs.

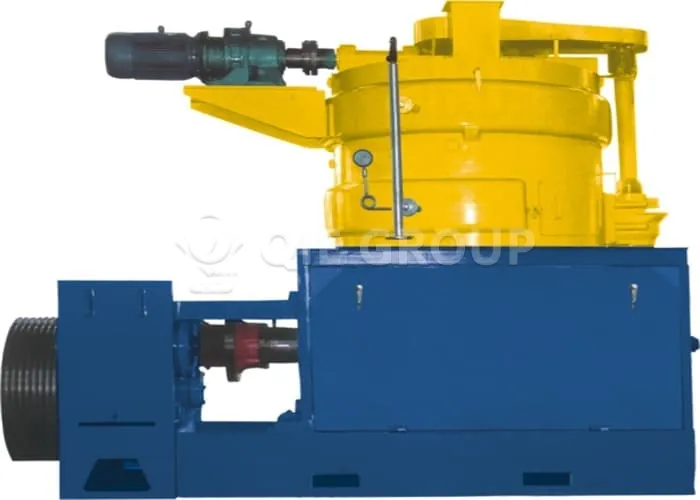

QIE Group's cold-pressed sesame oil equipment is designed to address these pain points. Our independently developed twin-screw low-temperature pressing system can strictly control the temperature below 60℃, maximizing oil quality and nutritional value while avoiding the damage caused by traditional high-temperature pressing. We provide a complete process chain solution, from raw material cleaning, drying and conditioning, low-temperature pressing, oil residue separation to automatic temperature control. We don't just sell machines; we provide complete production line solutions. 🔗 [ Twin-screw oil press | QIE Group low-temperature cold-pressing equipment ]

| Core advantages | Technical Highlights |

|---|---|

| Twin-screw cryogenic pressing system | The pressing temperature is controlled below 60℃ to preserve the original aroma, vitamin E and sesamin of sesame to the greatest extent. |

| High-strength alloy steel pressing chamber | With a wear resistance life increased by more than 3 times, it is suitable for sesame processing with high sand content in Ethiopia. |

| Modular design | Offering different production capacities, suitable for startups or large-scale processing plants. |

In response to the challenges of unstable power supply, a shortage of skilled workers, and limited maintenance conditions in the African market, our equipment incorporates the principles of "low failure rate, ease of operation, and minimal intervention."

1️⃣ Automatic voltage fluctuation protection;

2️⃣ Real-time fault code prompts;

3️⃣ Remote diagnostic interface to reduce downtime risk.

In the edible oil processing industry, customers are always most concerned about oil yield and operating costs. Take the LYZX series we delivered to Ethiopia as an example:

Behind these data lies our continuous investment in materials science, fluid mechanics, and thermodynamics. For example, our unique progressive compression ratio screw design ensures that sesame seeds are subjected to uniform force within the pressing chamber, preventing localized overheating that could lead to protein denaturation or oil oxidation. The intelligent temperature control system can adjust the electric heating and water cooling circulation in real time to ensure that the pressing process is always within the optimal temperature window.

Furthermore, the entire production line supports fully automated PLC control. Operators only need to set parameters on the touchscreen to achieve fully automated operation from material feeding to oil output. For customers who wish to build a modern factory, an MES system can also be integrated to achieve production data traceability, energy consumption analysis, and remote operation and maintenance management.QIE Group built a 1,500-ton-per-year cold-pressed sesame oil production line for a client in Ethiopia. Facing challenges such as seasonal raw material shortages, batch power supply, and a lack of skilled workers, we offered:

1️⃣ Large-capacity buffer warehouse : to meet the concentrated processing needs during the harvest season;

2️⃣ Stabilized power supply and backup control system : adaptable to power grid fluctuations;

3️⃣ Full set of operation training : Engineers provide on-site debugging for up to 30 days.

Customer feedback after the project went into operation:

"The equipment operates stably, and the products have been successfully exported to countries such as the UAE and Saudi Arabia. The oil is clear and has a pure aroma. It sells for 15% more than imported oil in local high-end supermarkets, which greatly enhances the market competitiveness of local brands."

Such success is not an isolated case. We have delivered multiple edible oil pressing projects in African countries such as Nigeria, Tanzania, and Ghana, focusing on edible oil production and validating the potential and feasibility of the African market.

We are not just an equipment supplier, but a long-term partner for our clients. We are involved throughout the entire project, from process design and plant layout advice to equipment installation, operation training, and long-term maintenance, ensuring worry-free production for our clients.

| Customized design | We tailor the most suitable automated sesame oil production line according to the client's raw materials, production capacity, and budget. |

| Global delivery services | A mature logistics system ensures worry-free, one-stop delivery of the entire equipment line, including sea freight, customs clearance, and land transportation. |

| Localization technical support | Supported by the East Africa Technical Service Center, with key spare parts readily available in stock, and a response time of no more than 72 hours. |

Q1: What is the difference between cold-pressed sesame oil and hot-pressed sesame oil?

A: Cold-pressed sesame oil is produced at a temperature controlled below 60℃ during the pressing process. It avoids high-temperature roasting or chemical refining, thus better preserving the natural aroma and nutrients of sesame seeds. While hot-pressed sesame oil has a slightly higher oil yield, its flavor is stronger, making it suitable for the low- to mid-range market. For export or high-end consumer markets, cold-pressed sesame oil is more competitive.

Q2 Can you assist me from the initial factory planning stage?

A: Of course. We can provide integrated solutions based on the client's factory area, production targets, and budget, including production line layout design, electricity and steam demand calculation, equipment selection, installation and commissioning, employee training, and other turnkey engineering services.

Q3: If the local power supply is unstable, will the equipment still be able to operate normally?

A: QIE's sesame oil cold press is equipped with an automatic voltage fluctuation protection system and supports a voltage regulator module, enabling stable operation within a voltage range of 160V–260V. It also supports a diesel generator backup power interface, ensuring continuous production even in rural areas.

Q4: Can QIE's equipment process other oils at the same time?

A: Yes. Our modular design allows for the replacement of the pressing screw and screen plate, and can be used for cold or hot pressing of oilseeds such as peanuts, sunflower seeds, sesame seeds, and cottonseeds, helping customers expand their diversified product lines.